Transmission: 4-Speed Sequential

Chassis Number: MK8\23\54

Engine Number: JAP

Colour: Silver metallic

1954 Cooper 500 Mk8\23\54 - for restorarion - NOW SOLD

JAP 4B - engine number 7058-79263/L built by Bill Needham of Cold Beck Engineering, bills dating from 1991 to 1992 - then owned and run in Norway as below.

Gearbox assembled by Bill Needham c1991 - bill on file

Returned to the UK from original export to the USA to Muriel Raby in 1989-90, it was then purchased by Eric Priestley in a crashed state with the intention of sprinting and hill climbing again, but as he says in an e-mail I received from him today - "but life got in the way!" He goes on to say that he obtained a replacement L/H rear corner and wheel, and had the remaining body repaired as you see in the last 2 photographs here, together with the fabrication of a new rear under tray. He intended to finish the restoration for competition but instead sold it to Roger Hurst of Kent who made him an offer he could not refuse. Roger Hurst even asked Eric Priestley to crate the whole project up and ship it to Norway - as it transpired to Per Gjerdrum of Hvalstad, Norway (specialising in Marine Pumps, / Liquid Mud Pumping systems / Compressors & Gas Turbines) - in October 1991 as a rebuild project in parts form & without engine - letter on file. On arrival in Norway without engine or gearbox, Bill Needham was commissioned to build a JAP 4B engine (now with BTH magneto - the then Coles coil ignition discarded) and Norton gearbox.

However - The 500 Owners Association has a record of Mk8\23\54 as follows : "Car number 147 - known but not seen since 1989. Originally exported to the USA, originally with Norton double overhead cam engine, last known being restored by Ian Raby in Brighton in 1989".

Bore 80mm / Stroke 99mm

Click on any photo to start a sequential slide show of photos

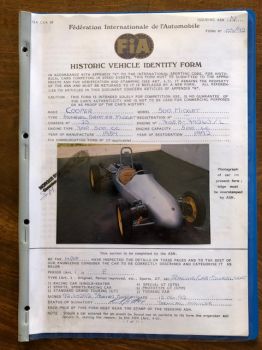

The Norwegian registered FIA Papers dated 1992, now expired, declare that a restoration was completed in 1992.

(See photo of FIA Vehicle Identity Form)

Currently owned in Ireland, this car has not been used in the last 10 years and previously to this, only used for demonstrations in Ireland and UK

This car would need careful recommissioning and I would suggest the following work is required:-

4 new tyres required – the Dunlop Racing Tyres date from 1991 from Vintage Tyre Supplies of Beaulieu. The 5.50L x 15" CR65 rears fitted at present would need to be Dunlop R5 to go with the fitted 4.50 x 15" R5 fronts

Brake overhaul - including 4 new wheel cylinders + master cylinder. Last done 1991 - bills on file

Brake hoses & pipes - renewal of

Brake reservoirs : renewal of both - (originals fitted)

Hand brake not working.

Engine may be gummed up - engine turns over

Twin-chamber Amal Mk2-2934 carburettor would need to be changed to an Amal Track Carb - type 27

Tanks - Oil and Methanol - will need cleaning

Constant loss oil catch tank cleaning

BTH Magneto might need a rebuild - new fitted c1991 by Bill Needham

15" Magnesium wheels inspection

Chain lube cross member tube tank will need cleaning out

A VERY TIDY EXAMPLE - indeed a straightforward restoration and recommissioning is required

_______________________________________

MkVII Cooper information

For 1954 a number of improvements and changes were made. The centrally mounted 8 gallon fuel tank was restored to above the knees which greatly reduced the frontal area of the car compared to the side tanks on the MkVI and MkVII

The largest change was to the chassis which was totally different and featured curved chassis tubes, the light chassis matching the shape of the bodywork, removing the need for the otherwise added weight of body supports.

An anti-roll front spring was devised in the form of a curved leaf which sits in the middle of the main spring which in turn is mounted on two pairs of rollers set on each side of the chassis. The curled leaf is attached to the upper roller on each side and to the centre of the main spring. This prevents the main spring from moving laterally but allows some vertical movement and exploits the anti-roll effect of transverse leaf springs. As one side of the main spring is forced up – when the car leans – so the curved leaf acts against the centre. The overall effect is a small amount of understeer and better stability in faster corners on the track.

Previous models of the Cooper 500 focused all the main masses as close to the centre of the car as possible, but the factory was concerned that the very low polar moment of inertia was allowing the cars to let go quite suddenly on the limit of adhesion. For the MkVIII some of the mass was moved to each end of the car to promote better stability – the fuel tank being moved forward and the constant loss oil tank moved to the extreme rear of the car.

All these changes enabled a very pretty torpedo body shape – and lowered. Body panels were in 3 sections and an undertray was attached directly to the chassis with Dzus fasteners, nose and tail sections hinged fore and aft to enable easy access.

The single cylinder JAP 4B Speedway engine was originally designed for use in Speedway bikes during the 1930s. A pushrod design uses a total loss lubrication system and is light and powerful due to a high compression ratio and the use of methanol fuel. The JAP 4B had a much improved performance over the Type 4 and 4A especially at higher RPM. Improved breathing was enabled by an increase in the inlet tract diameter. The big port engine has a 32mm inlet port compared to 28.5mm on the previous engines, and now used the Amal 932 carburettor adapted for methanol. The basic design was developed over 40 years of continuous racing – using Electron crankcases, a Dural con-rod, big end and main bearings in caged rollers and needle roller rocker levers. The engine is extremely simple to overhaul, requiring no special tools, and usually completely reliable and efficient. Compression ratio 15:1, weight 63lbs, magneto 2 3/4lbs, Carburettor 2lbs. NGK B9HN. Methanol. Castrol R.

Two versions of the MkVIII were available, this being the T31 with 500cc. By now Cooper dominated Formula 3 here in the UK and also in Europe. The Works team cars were piloted by Les Leston and Stuart Lewis-Evans with Sir Stirling Moss when available. Works Jaguar Le Mans driver Ivor Bueb and race driving school proprietor Jim Russell also bought MkVIIIs which they used to great effect. Ivor Bueb’s car had a considerable weight loss advantage of 20lbs – achieved by drilling a number of holes, we understand to compensate for his liking for food!

Indeed Les Leston became the 1954 Formula 3 champion in his MkVIII Cooper – something to note!

Call 07973 731508